FILTER ELEMENT

Spun Bonded Filter Cartridge

Spun Bonded Filter Cartridges are made up of 100% polypropylene fibers. The fibers have been carefully spunned together to form a true gradient density from outer to the inner surface. Filter cartridges are available with both core & without core version. The superior structure remains integral even under severe operating conditions and there is no media migration. Polypropylene fibers are blown continuously on the central molded core, without any binders, resins or lubricants.

Features :

-

Consistent and Reliable Performance

-

Excellent Flow with Low Pressure Drop

-

High Dirt Holding Capacity

-

100% Polypropylene for Wide Chemical Compatibility

-

High Strength & Pressure Resistance

-

Nominal Filtration Rating

-

Graded depth filtration gives excellent performance

Technical Specification:

Size :10″, 20″, 30″, 40″, 50″, 60″

Outer Diameter :2.5″, 4″, 4.5″

Inner Diameter :28 mm

Micron Rating :1, 5, 10, 25, 50

Configuration :Double Open End (DOE), SOE

MOC :100% Polypropylene

Application :

-

Water Treatment

-

Pharmaceuticals

-

Refineries

-

Chemicals

-

Coolant filtration

-

Solvent

-

Other Liquid

-

Acid Filtration

-

Alcohol Filtration

-

Organic Acid

Wound Filter Cartridge

Wound Filter Cartridges are designed to meet the most demanding filtration duties. They offer an economic, compact, easily installed and maintained filtration system for removal of particles from liquid. Wound cartridges are manufactured from a variety of carefully selected raw materials. These are processed into fibers of specific grades using the latest technology. After carding & spinning into roving they are wound into cartridges with cautiously controlled micron rating. From raw materials to finished products we are in control of the quality and filtration characteristics. They are appreciated due to its high dirt holding capacity and rugged construction that allows facing different applications in liquid and gas filtration

Features:

-

High Strength

-

Min. Pressure Drops

-

High Flow Rate

-

East to installation

-

High Dirt Holding Capacity

Technical Specifications :

MOC: PP Yarn with PP Core, Glass Fiber Yarn with SS Core

Size : 10″, 20″, 30″, 40″

Outer Diameter : 2.5″, 4″, 4.5″

Inner Diameter: 28 mm, 50mm

Micron Rating: 1, 5, 10, 25, 50, 75, 100

Configuration: Double Open End (DOE)

Application:

-

Organic Acids

-

Oils

-

Concentrated Alkalis

-

Water

-

Organic solvents

-

Electroplating solution

-

Photographical process fluid

PP Pleated Cartridge

Polypropylene filter cartridges are precisely manufactured for use in critical filtration applications within food, pharmaceuticals, biotech, dairy, beverages, semiconductor, water treatment & other demanding process industries. Polypropylene pleated cartridges use the very latest gradient density micro fiber media technology to provide a combination of excellent micron ratings, high flow rates and high contaminant holding capacities. A special combination of polypropylene media with variation in the fiber diameter creates a gradient density matrix, ranging from open on the outside to finer on the inside, thereby providing a filter with in filter, which considerably increases contamination holding capacity & throughputs. All components used in the manufacturing process are biologically safe, chemically inert and meet FDA and other international quality requirements. Polypropylene offers an extremely broad chemical compatibility making it suitable for many applications.

Features:

-

Fine filtration

-

Min. Pressure Drops

-

High Flow Rate

-

Welded Construction

-

Easy to install

Technical Specification:

Size :10″, 20″, 30″, 40″

Outer Diameter :68 mm

Inner Diameter :28 mm

Micron Rating :0.2, 0.45, 1, 5, 10

Configuration : DOE, CODE-7

MOC :PP

Application:

-

RO & DM Water

-

Pharmaceutical Industries

-

Inks & Paints

-

Food & Beverages

-

Oil & Chemicals

-

Air & Gas Filtration

PTFE Filter Cartridge

PTFE Cartridges are made up of poly tetrafluoroethylene. PTFE is characterized by high chemical inertness. These are specifically designed for sterile filtration applications of liquid, air & gas streams. They are certified, bio-safe, non-pyrogenic & fully validated to pharmaceutical standards. PTFE used in cartridge manufacturing are chemically inert, not shedding and biologically safe according to F.D.A., USP and EEC requirements for pharmaceutical and food contact usages. PTFE cartridge membrane is used in filtering the highly corrosive solutions such as strong acids, base solution, and solvents. The membrane has about 80 – 95 % porosity & uniform pore size distribution.

Features :

-

PTFE membrane has excellent chemical resistance.

-

End caps and connectors are sealed by thermal bond, free from binder.

-

Low pressure drop and high flow rate due to high filtration area of 0.5 m2 Per 10” cartridge.

-

Inherently hydrophobic expanded PTFE micro porous membrane for broad chemical compatibility & to prevent moisture obstruction in venting & wet air filtration.

-

Absolute rated & precisely controlled pore size distribution for superior & constant bacterial retention.

-

Autoclave or in situ steam sterilization features.

-

Integrity test is possible.

-

FDA approved.

Technical Specification:

Sizes :10”, 20”,30”40” Long

Micron Rating :0.1, 0.2, 0.45 , 1 Micron

Filtration Area : 0.5 m2 Per 10” cartridge

Application:

Pharmaceuticals

Sterilization of inlet & exhaust flow

Vent filter

Gas purification (like nitrogen & others)

Compressed air (sterile grade)

Acid / Solvents & base filtration

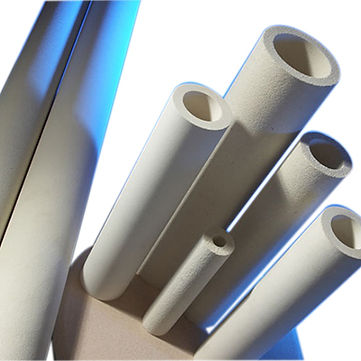

Ceramic Filter Cartridge

Sintering is a process for making element from its base material in powder form .They are made by mixing elemental or alloy powders and compacting the mixture in a die, the resultant shapes are then sintered or heated in a controlled atmosphere furnace to bond the particles. Sintering is traditionally used for manufacturing ceramic objects and after that it is used for filtration application. Due to sintering process, particles join with each other and form a porous structure which allow any fluid , air or gas to pass through without disturbing its structure. This structure is robust in nature to handle particle above stipulated micron rating. Such elements are back washed some time for cleaning purpose to remove deposited particle load. These sintered solid filters are able to withstand very high differential pressure across the filters.

Features :

-

Specific Pore size distribution due to sintering process.

-

Withstand very high differential pressure.

-

High void volume compared to conventional sintered material.

-

Easy to clean & back wash.

-

Wide chemical compatibility.

Technical Specification :

MOC : Sintered Ceramic

Size : 10”, 20”, 30”, 40”

Outer Diameter : 70 mm

Inner Diameter : 40 mm

Micron Rating : 1, 5, 10, 25

Configuration : DOE

Application :

-

Water

-

Solvents

-

Coolant Oil

-

Air & Gas Filtration

-

Chemicals

-

Magnetic Coating

Resin Bonded Filter Cartridge

RB (Resin-Bonded) Cartridge is produced from cellulose fibers, and Acrylic Fibers which have been intrinsically bonded together by a melamine Phenolic resin, to create a solid highly durable & porous structure.

Features

-

Consistent and Reliable Performance

-

Excellent Flow with Low Pressure Drop

-

High Dirt Holding Capacity

-

100% Polypropylene for Wide Chemical Compatibility

-

High Strength & Pressure Resistance

-

Nominal Filtration Rating

-

Graded depth filtration gives excellent performance

Technical Specification:

MOC : Cellulose Resin Bonded

Size : 10”, 20”, 30”, 40”

Outer Diameter : 62.5 mm, 70 mm

Inner Diameter : 25 mm, 28 mm, 30 mm

Micron Rating : 0.2, 0.4, 0.7, 1, 5, 10, 25, 50, 75, 100

Configuration : DOE

Construction : Grooved, Un-Grooved

Application:

-

Water

-

Chemicals

-

Paints

-

Inks

-

Organic Solvents

-

Lube Oil

-

Edible Oil

-

Resins

-

Air & Gas

-

Pharmaceuticals

Sintered Powder Filter Cartridge

Features:

-

High Strength

-

Min. Pressure Drops

-

High Flow Rate

-

Easy to clean

-

Easy to installation

-

High Dirt Holding Capacity

-

High Temperature

Technical Specification::

MOC : SS316L, SS316

Size : 10” , 20”, 30”, 40”& Customized

Outer Diameter : 50 mm, 64 mm, 76 mm

Inner Diameter : 28 mm & Customised

Micron Rating : 0.2, 0.45, 1, 5, 10, 20, 25, 50

Connection : DOE, SOE, Code-7 & Customised

Application :

-

Hot Gas

-

Catalyst Recovery

-

Slurry Oil

-

Petrochemicals

-

Compressed Air,

-

Vent

SS Wire Mesh Filter Cartridge

Features:

-

East to installation

-

High Strength

-

Max. Flow Rate

-

More Filtration Area

-

Re-usable / Washable

-

High Dirt Holding Capacity

Technical Specification :

MOC : SS304,SS316 (Wire Mesh) / SS316L

Size : 10″, 20″, 30″, 40″ & Customized

Outer Diameter : 2.5″, 4″, 4.5″, 6″ & Customized

Inner Diameter : 28 mm & Customized

Micron Rating : 5, 10, 25, 50, 100

Connection : DOE, SOE, Code-7 & Customized

Type : Cylindrical & Pleated

Application :

-

Water

-

Oil

-

Chemicals

-

Solvent

-

Ceramics

-

Sand

Basket Filter Element

Features:

-

East to installation

-

High Strength

-

High Flow Rate

-

High Filtration Area

-

High Dirt Holding Capacity

Technical Specification:

MOC : SS316, SS304,

Size : Customized (as per customer requirement)

Micron Rating : 5, 10, 25, 50, 100 … & More

Type : Cylindrical, Tapered, Pleated

Application :

-

Water

-

Oil

-

Chemicals

-

Solvent

-

Ceramics

-

Sand

Paper Pleated Filter Cartridge

Features :

-

High Efficiency

-

Min. Pressure Drops

-

Large surface Area

-

High Flow Rate

-

East to installation

-

Superior Solids Holding Capacity

Technical Specification :

Media : Paper, Synthetic, Polyester, HDPE

Size : 10” , 20”, 30”, 40”& Customized

Outer Diameter : 2″, 2.5″, 4″, 4.5″ & customized

Inner Diameter: 28 mm & Customised

Micron Rating: 1, 5, 10, 20, 25, 50, 100, 250

Connection : DOE, SOE, Customised

MOC of Caps : SS/MS/GI/Allu.

Application :

-

Lube Oil

-

Synthetic Oil

-

Insulating Oil

-

Cutting Oil

-

All Hydrocarbon Fuels

-

Diesel Fuel

-

Hydraulic Oil

High Flow Filter Cartridge

PP Pleated and glass fiber cartridges are designed for higher filtration area & high throughput. It has large diameter with an inside to outside flow pattern. Due to its large diameter with big filter area, it requires lesser elements for a given flow rate than standard cartridges diameter. Due to lesser elements, the Filter vessels ‘s size workout is smaller, resulting in lower capital investment and installation costs, as well as reduced operating costs.

Features :

-

Minimize overall size of filter housing due to its high throughput.

-

Absolute rated filtration efficiency

Technical Specification:

Filter media : glass fiber, Polypropylene (PP)

End cap : Glass fiber reinforced Polypropylene

O-ring seal : EPDM, NBR

Sizes: 20.“, 30'',40 ” etc

Micron Rating: 1, 4.5, 6, 10,20,40,70,100 Microns

Outside Diameter: 6 inch

Application :

-

API, solvents, and water filtration in Biopharma market.

-

edible oil, soft drinks, and milk.

-

Paints and coatings, Petrochemical, Refineries.

-

Microelectronics, film, fiber, and resin.

-

Aviation Turbine Fuel, High sulfur diesel fuel ( HSD), etc.